TRUE-LOAD MENU

MotionPort Introduces Load Reconstruction Software

The RecurDyn Need

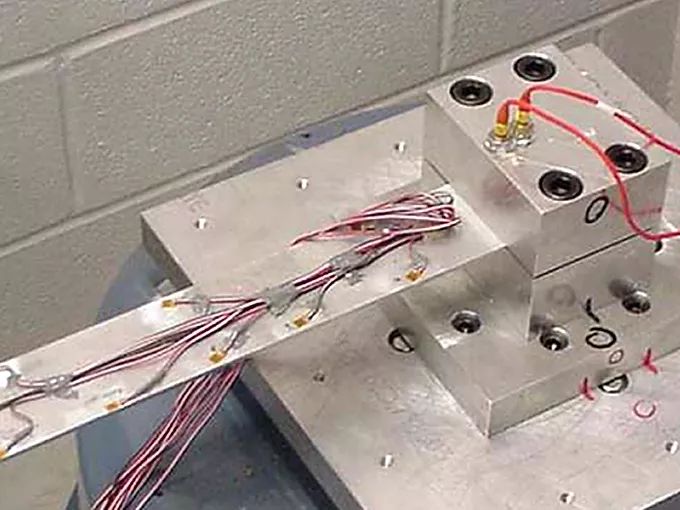

When seeking to validate a RecurDyn model, it is often convenient to compare the load history with the results of physical testing because loads are available at the joints between bodies. Unfortunately the loading profile is often the biggest unknown in a physical. While load transducers can be used in some cases, testing with load transducers can be expensive and the inclusion of load transducers can change the load path resulting in inaccurate loads.

It would be helpful if we could determine the loading profile from a test event using inexpensive strain gauges, but this leaves an analyst with the job of manually adjusting the load to correlate the FEA model of the instrumented body with strain data. This can take several hours of effort just to correlate one or two strain gauges at a single point in time.

How True-Load Fits In

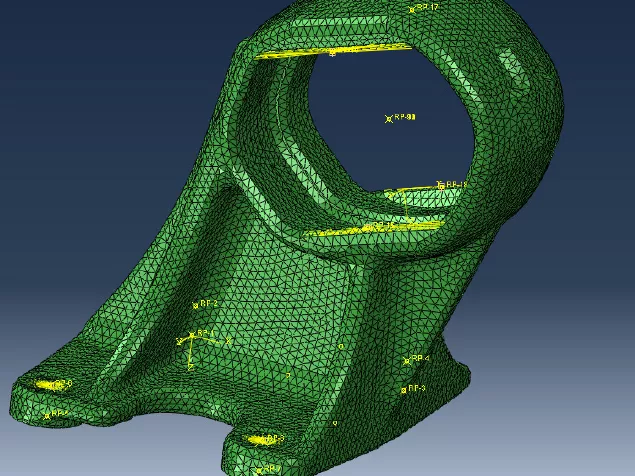

All of the difficult correlation work can be done for you using True-Load. True-Load first uses an FEA model to determine the optimal strain gauge placement to ensure that you are gaining as much information as possible from your testing.

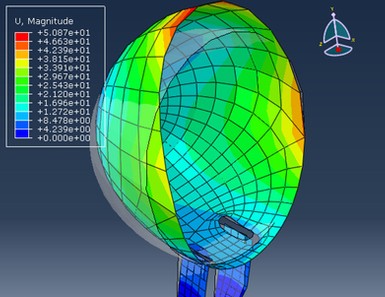

Then, once strains are collected at these optimal gauge locations, the strain data is read into True-Load to calculate load time histories that will typically match the measured strain to within 2% at every point in time.

Typically, it only takes a few minutes to determine the strain gauge placement and a few minutes to back calculate the loading profiles.

When combined with True-QSE (Quasi-Static Events), interrogating any point in the model for strain, stress or displacement is easy and interactive. You now have a validated FEA model with full field knowledge using only a handful of strain gauges. The associated load histories can be used to validate your RecurDyn model.

Why Select True-Load?

True-Load is a first to market to solution that leverages FEA models to place strain gauges on unmodified physical parts and then back calculate loading. Output directly feeds into True-QSE events, a powerful post processing tool that supports rapid virtual iteration. True-Load includes a direct interface to FEA based fatigue. Note that several of our RecurDyn clients are also using True-Load. Now you have the opportunity to also benefit from the synergy of RecurDyn with True-Load.

About Wolf Star Technologies

Wolf Star Technologies has unique, first-to-market solutions that meet the fundamental needs of engineers / analysts working with FEA tools. Our software packages, True-Load, True-QSE and True-LDE, bring understanding to dynamic loading of structures and extract decision ready data from FEA models.

MotionPort arranged with Wolf Star Technologies to host a special True-Load webinar just for our clients and friends. Dr. Tim Hunter, President of Wolf Star Technologies, presents an overview of this first-to-market software solution with real world examples.

To view the webinar, please enter your email address below to unlock the video player.

“The implementation of the Abaqus / True-Load process increases Trek’s knowledge of loading environments and aligns with Trek’s history of innovation and reliability.”

– Jay Maas, Analysis Engineer at TREK BICYCLE COMPANY

“By using True-Load software to recreate time-varying field loads and applying those loads to our simulation models, we have achieved exceptional correlation between simulated strain and measured test strain. This accuracy combined with the ability to use True-QSE to evaluate the entire structure has greatly improved confidence in designs validated through simulation. The end result is fewer design and test iterations.”

– David Slowinski, Design Analysis at CNH INDUSTRIAL

“Determining loading functions that are representative of real life to simulate the structural response of a new lawnmower chassis concept would be guesswork without True-Load. The seamless interface between Abaqus/CAE, fe-safe, and True-Load make determining the structural integrity of new designs a fast, accurate, easy process.”

– Aleysha Juntunen, Engineering Analyst at ARIENS

More Information

- Wolf Star Technologies

- Request more information about this and other software modules.